How Plastic Curtains Improve Environmental Separation

Understanding Environmental Separation Using Plastic Curtain

Plastic curtains basically set up different environmental areas because they work like bendy see-through walls. These aren't your regular walls or standard doors though. They keep spaces separate but let people and machines move back and forth without stopping. The way these curtains overlap with their PVC strips cuts down on air mixing between rooms, which is why many places need them when controlling temperatures matters a lot, think food factories or drug manufacturing plants. Some research from the Air Quality Institute last year showed something interesting too. When installed right, these plastic barriers can cut down contamination problems by around two thirds in facilities dealing with stuff that needs special care. Of course, getting the installation correct makes all the difference here.

How Clear PVC Plastic Sheeting as a Protective Barrier Enhances Indoor Air Quality

PVC strip curtains do a pretty good job at filtering out airborne particles without blocking sightlines completely. What makes them work so well is that static electricity in the material pulls in dust and pollen before they can get into sensitive areas. Paint shops in the automotive industry find these particularly useful for trapping overspray particles, which keeps neighboring work areas much cleaner than traditional methods. According to some recent industry studies, facilities using these strips saw particulate levels drop around 58% compared to when doors were left open during operations, according to Canada Plastics report from last year.

Phenomenon of Air Infiltration and the Plastic Curtain Solution

The Department of Energy reports that air leaks can cause anywhere from 30 to 40 percent of all energy losses in industrial buildings. Plastic strip curtains tackle this problem with heavy bottoms that stay put and overlapping panels that actually fit around machinery instead of just hanging there useless. One warehouse saw their heating bills drop by almost 27% once they put these things up at loading docks, according to Pressford Shutters research from last year. What makes them work so well is how they slow down airflow without completely sealing everything off. This lets temperatures balance out naturally over time rather than creating those hot and cold spots we all hate. Plus, workers can still walk through easily when needed, which solves another common complaint about traditional door systems.

Principle of Thermal and Particulate Containment With PVC Strip Curtains

PVC's low thermal conductivity (0.19 W/m·K) enables it to act as an effective insulation buffer. In cold storage, plastic curtains maintain temperature differentials during forklift access, minimizing frost formation on perishables. For particulate containment, two mechanisms are key:

- Interception: Strips physically block larger particles (>10µm)

-

Electrostatic adsorption: Negatively charged PVC captures fine dust (<2.5µm)

Together, these actions make PVC strip curtains 89% effective at preventing outdoor pollutants from entering cleanrooms, based on 2023 material safety testing data.

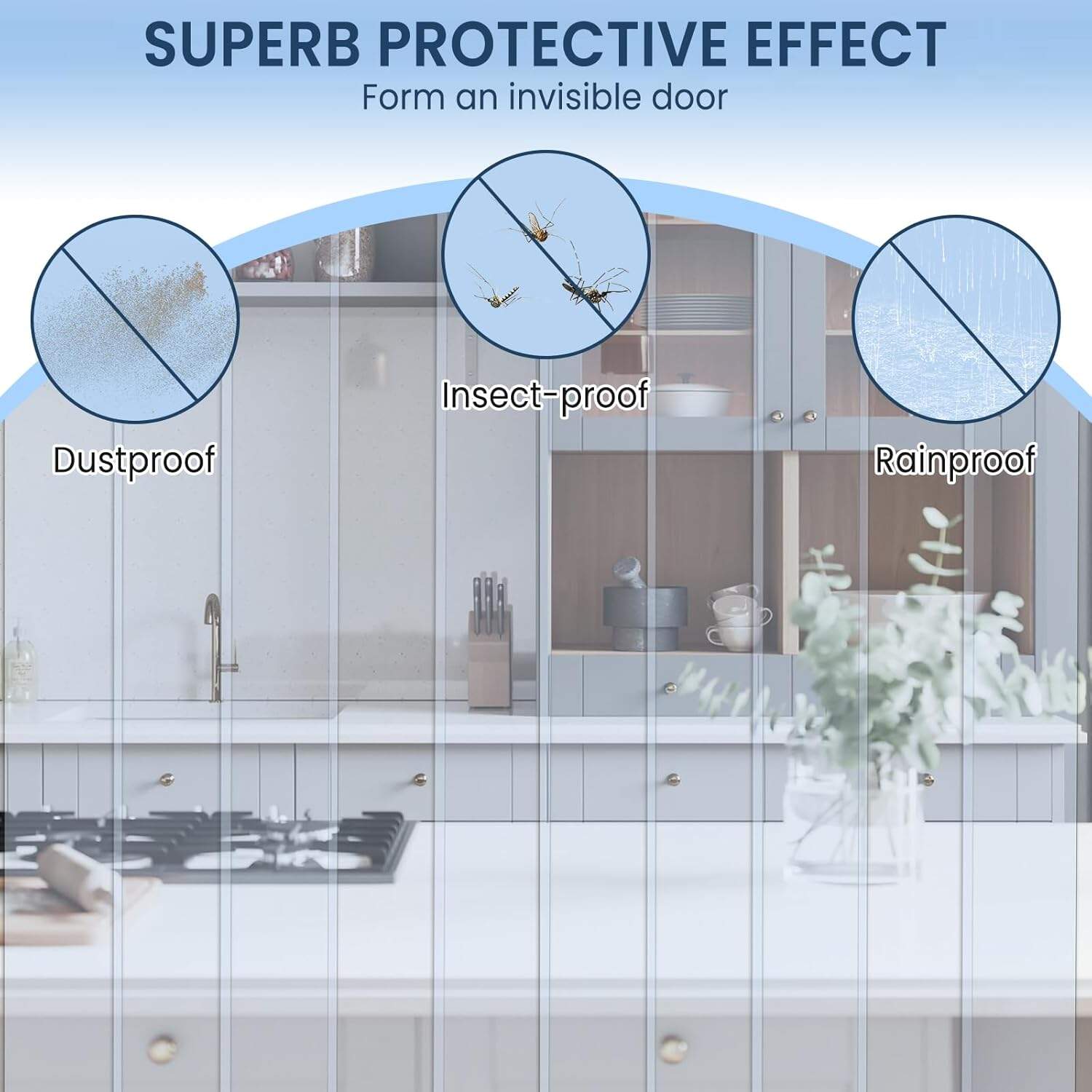

Wind and Dust Protection Mechanisms of Plastic Curtains

Weather Protection Using Plastic Curtains in High-Exposure Zones

Plastic curtains serve as robust weather-resistant barriers in harsh industrial environments. Facilities using PVC strip curtains reported a 62% reduction in wind-driven debris ingress compared to open doorways. The overlapping strip design dissipates wind pressure while allowing continuous access—essential for loading docks, agricultural storage, and mining operations.

Strategy for Optimal Installation Height and Overlap to Maximize Wind Protection

Maximizing wind deflection depends on precise installation:

- Overlap ratio: 30–50% coverage between adjacent strips disrupts airflow continuity

- Ground clearance: Maintaining less than 2 cm gap prevents wind tunneling while accommodating floor cleaning

- Header seals: Reinforced top mounts eliminate gaps at structural joints, enhancing overall barrier integrity

Dust and Debris Control in Manufacturing with Industrial Curtains as Physical Barriers Against Pollutants

Plastic curtains reduce airborne particulate concentrations by 40% in manufacturing settings. Their electrostatic-resistant surfaces trap dust particles as small as 10 microns, offering critical protection in electronics assembly and pharmaceutical cleanrooms where contamination control is paramount.

Health and Safety Benefits of Controlling Dust Exposure via Plastic Curtain Enclosures

Sealed plastic curtain systems help maintain OSHA-compliant respirable dust levels below 5 mg/m³ in high-dust operations like woodworking and metal grinding. Facilities using USDA-certified curtains report 28% fewer respiratory incident reports than those with open workspaces.

Key Industrial and Construction Applications of Plastic Curtains

Streamlining Workflow With Dust and Contaminant Control in Industrial Environments

In food processing plants and automotive factories, plastic curtains actually boost how work gets done because they create separate zones for different environments. Recent research from last year found that when these heavy duty PVC curtains were put in place, there was almost two thirds fewer cases where things got contaminated across different areas. These curtains catch floating particles in the air while still letting people see through them and move around freely. For best results, most experts recommend having the strips overlap between eighty to ninety percent. This level of coverage meets those strict ISO 14644-1 standards for clean air that many manufacturing facilities need to follow, especially where products are really sensitive to contamination.

Durability and Resistance to Environmental Factors in 24/7 Warehouse Operations

High-traffic warehouses rely on heavy-duty vinyl curtains to endure constant forklift traffic and extreme temperatures ranging from -40°F to 160°F. UV-stabilized PVC remains flexible after 50,000+ opening cycles, outperforming traditional barriers. This durability is especially valuable in cold storage logistics, where uninterrupted operation is essential.

Barrier Against Wind and Outside Air Infiltration During Building Renovations

Transparent plastic curtains help maintain climate control in partially enclosed structures during renovations, cutting HVAC energy costs by up to 30%. Overlapping strips with weighted bottoms resist wind gusts of 15–20 mph, containing debris while allowing seamless transport of materials through temporary openings.

Use of Vinyl or Heavy-Duty Materials for Environmental Barriers on Scaffolding and Openings

Scaffold-mounted PVC curtains with reinforced grommets provide OSHA-compliant fall protection and dust containment at heights over 50 feet. A 2022 case study in high-rise refurbishments showed that 14oz/sq.yd vinyl barriers reduced airborne silica dust by 78% compared to polyethylene sheets, while resisting UV degradation and mechanical damage from construction equipment.

Material Innovations and Performance Enhancements in Plastic Curtains

Advancements in Use of Heavy-Duty Materials for Long-Term Weather Barrier Applications

Today's plastic curtains are made from special polymer mixes that include UV protection additives and impact resistant components, which can actually double their lifespan compared to older materials in some cases. Manufacturers now use multi layer extrusion methods to create stronger core structures in these sheets, resulting in tensile strength numbers around 2,100 psi according to recent industry reports from 2025. What this means for real world applications is that modern plastic curtains hold up remarkably well under tough conditions. They stay flexible even when exposed to freezing temperatures inside cold storage facilities or subjected to intense heat in metalworking environments like foundries where traditional materials would typically fail.

Comparative Analysis: Standard Polyethylene vs. Reinforced PVC Strip Curtains

| Property | Standard Polyethylene | Reinforced PVC |

|---|---|---|

| Abrasion Resistance | Moderate (1,200 cycles) | High (3,500+ cycles) |

| Transparency Retention | 70% after 1 year | 92% after 1 year |

| Cold Crack Resistance | -10°F | -40°F |

Reinforced PVC offers superior durability in high-traffic areas, reducing replacement frequency by 60% and maintaining significantly clearer visibility over time.

Future Trend: Self-Healing and Anti-Static Plastic Curtain Coatings

New nanotech coatings are making plastic curtains self-healing against small scratches and holes, cutting down on repairs. Some early tests have shown maintenance expenses dropping nearly four fifths. For places where dust and static are problems, special anti-static treatments help surfaces stay clean longer. These treatments bring surface resistance down under 100 million ohms per square, something that matters a lot in factories building delicate electronic components. As companies push harder toward greener operations, these smart coatings look set to become much more common. Industry forecasts suggest adoption rates could jump around 35 percent by mid decade, fueled by new materials research that fits well with worldwide environmental, social and governance standards many corporations are adopting these days.

FAQ

What are plastic curtains used for?

Plastic curtains are used to improve environmental separation, control air infiltration, and manage dust and debris in industrial settings.

How do PVC strip curtains enhance air quality?

PVC strip curtains filter airborne particles by utilizing static electricity to capture dust and pollen, improving indoor air quality.

Can plastic curtains reduce energy costs in buildings?

Yes, plastic curtains help reduce energy costs by minimizing air leaks, thereby improving insulation and reducing heating and cooling expenses.

What materials are used to make durable plastic curtains?

Durable plastic curtains are often made from reinforced PVC with UV protection additives and impact resistant components to extend their lifespan.

Table of Contents

- How Plastic Curtains Improve Environmental Separation

-

Wind and Dust Protection Mechanisms of Plastic Curtains

- Weather Protection Using Plastic Curtains in High-Exposure Zones

- Strategy for Optimal Installation Height and Overlap to Maximize Wind Protection

- Dust and Debris Control in Manufacturing with Industrial Curtains as Physical Barriers Against Pollutants

- Health and Safety Benefits of Controlling Dust Exposure via Plastic Curtain Enclosures

-

Key Industrial and Construction Applications of Plastic Curtains

- Streamlining Workflow With Dust and Contaminant Control in Industrial Environments

- Durability and Resistance to Environmental Factors in 24/7 Warehouse Operations

- Barrier Against Wind and Outside Air Infiltration During Building Renovations

- Use of Vinyl or Heavy-Duty Materials for Environmental Barriers on Scaffolding and Openings

- Material Innovations and Performance Enhancements in Plastic Curtains

- FAQ