What is PVC Clear Sheet? Chemical Composition and Key Characteristics

Polyvinyl Chloride Polymerization Process Explained

PVC starts forming through a polymerization process where manufacturers typically use methods like suspension or emulsion polymerization. Basically, this turns vinyl chloride monomers into long polymer chains that become polyvinyl chloride we know as PVC. Chlorine is really important in how PVC behaves chemically. It gives the material those useful traits like being resistant to fire and lasting longer over time. Without enough chlorine content, PVC wouldn't hold up so well under stress or extreme conditions. During manufacturing, companies throw in all sorts of additives depending on what they need the final product to do. Plasticizers go in there to make things bendy instead of brittle, while stabilizers help fight off degradation when exposed to sunlight or harsh weather. This whole mix of chemical tweaks explains why clear PVC sheets work so well across different industries from construction to signage fabrication.

Impact Resistance Comparison with Traditional Materials

Clear PVC sheets stand out because they just don't break like regular glass or acrylic does. Look at the numbers and it becomes pretty obvious why so many people choose PVC over other options. When something hits them hard, these sheets take the hit instead of cracking apart. We've seen test results showing this time and again in manufacturing settings. Glass tends to go splintering everywhere under similar stress conditions. That's why auto makers and builders keep coming back to PVC for things like protective covers and windows. The stuff actually soaks up impacts without going all fragile on us. Safety conscious businesses across different sectors find this property incredibly valuable, especially in places where accidental damage could lead to serious problems down the road.

UV Stability and Weather Resistance Properties

PVC clear sheets have excellent UV stability that makes them stand out against most other plastics since they don't break down easily when hit by sunlight. Looking at how long these sheets last in different conditions shows they hold up pretty well against all sorts of weather without falling apart much. Some testing has shown that PVC doesn't turn yellow as quickly and stays clearer longer than regular plastic alternatives. This means the material lasts longer before needing replacement which cuts down on maintenance expenses, especially important for things like greenhouses or signs placed outside. Because PVC resists UV damage so well, companies don't have to replace or fix these materials nearly as often, making it a smart choice economically for anyone dealing with products exposed to harsh environments.

Flexible Yet Durable Surface Qualities

PVC clear sheets strike just the right mix of bendy and tough, which is why they work so well across many different situations. From what we know about how materials behave, PVC manages to stay soft enough when needed but still holds up against wear and tear over time. Take warehouse environments for instance. Many facilities install these flexible PVC sheets as door curtains between storage areas. The material bends easily as people or equipment pass through, yet doesn't break down after months of constant movement. Same goes for magnetic door curtains that need to stick properly while remaining pliable enough not to crack. Companies in manufacturing and logistics report good results from switching to flexible PVC products, especially since their operations put regular strain on materials day after day. For businesses looking at cost-effective options that last, PVC's blend of flexibility and strength makes it stand out among other alternatives available today.

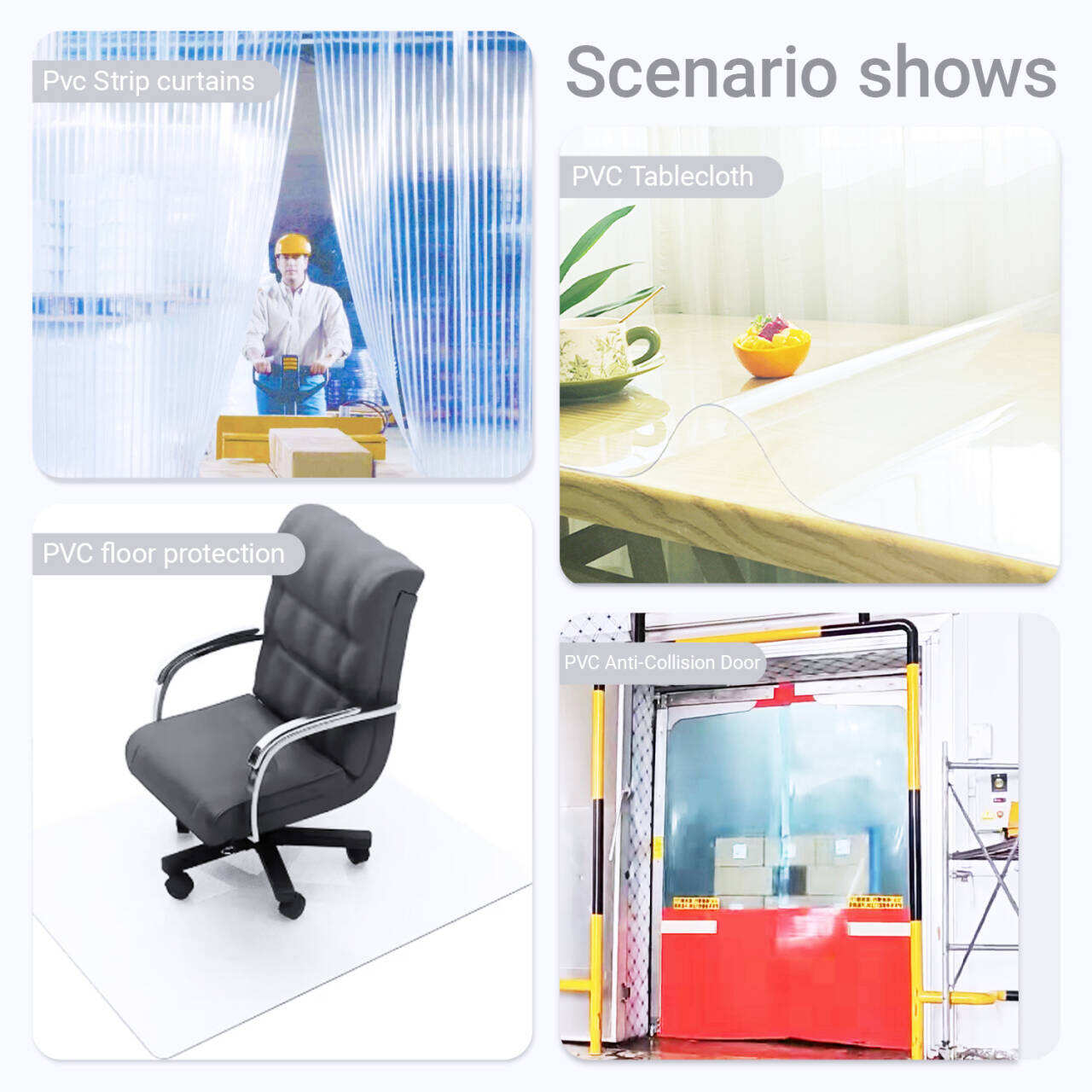

Top Applications of PVC Clear Sheets Across Industries

Industrial Flexible Plastic Curtains for Temperature Control

Flexible plastic curtains are making a big difference when it comes to keeping temperatures stable in places like factories and warehouses where climate control matters. These plastic barriers help separate off areas that need specific temperature conditions, cutting down on heat transfer between different zones which wastes energy. Many warehouse managers report seeing their electricity bills drop after installing these flexible PVC sheets because they actually work better at insulating than traditional methods. Some companies even claim around 30% less energy consumption once these curtains go up, though installation does require proper planning for maximum benefit. The bottom line is that these plastic solutions not only save money but also make facility management easier in the long run.

Clear Strip Curtain Doors in Warehouses and Retail Spaces

Clear strip curtain doors have become essential in warehouses and retail areas because they let people and products move around easily while keeping pests out. The plastic strips create a barrier that stops insects and other unwanted critters from getting inside, which helps maintain clean conditions especially important for places where food is handled. Many businesses find it much easier to meet FDA food safety standards when using these types of doors. Real world experience shows that companies installing clear strip curtains often see better workflow efficiency since the doors separate different areas without creating obstacles. Some stores even mention fewer complaints about cleanliness issues after switching to this type of door system.

Heavy Duty PVC Strip Curtains for Manufacturing Facilities

Heavy duty PVC strip curtains get made specifically for tough manufacturing settings where regular stuff just won't cut it. These curtains come thicker and stronger than standard versions, which means they can handle all sorts of rough treatment and still hold up against the dirt, dust, and chemicals common in factories. Tests have shown these heavy duty options last way longer than normal curtains too sometimes doubling or even tripling their lifespan. People working in places like car plants and meatpacking facilities report these strips perform much better over time while costing less overall compared to cheaper alternatives that need constant replacing.

Magnetic PVC Door Curtains for High-Traffic Areas

Magnetic PVC door curtains work really well in places where lots of people come and go all day long. They help keep things moving smoothly between spaces while still keeping dust, noise, and temperature changes at bay. What makes them special is those magnetic strips along the edges that stick together when the curtain closes, creating a pretty good seal against outside air. According to some studies, companies that install these kinds of doors often see their energy bills drop quite a bit because cold or hot air doesn't leak through anymore. Warehouses and big stores tend to use magnetic door systems most frequently since they need both easy access for workers and trucks but also want to save money on heating and cooling costs over time.

Protective Barriers in Healthcare and Food Processing

Protective barriers play a really important role in keeping things clean and stopping germs from spreading in healthcare settings and food processing plants. Clear PVC sheets are a big part of creating sterile environments that meet strict health standards set by organizations like the CDC and World Health Organization. These plastic barriers work well to separate different areas, which helps prevent cross contamination and keeps both medical supplies and food items safe. Research has shown that using PVC sheets actually reduces risks and makes safety procedures better across the board. For businesses where mistakes can be costly, these simple but effective barriers have become almost indispensable over time.

Performance Benefits: Why PVC Outperforms Alternatives

Chemical Resistance Against Harsh Environments

PVC clear sheets stand up really well against chemicals, which makes them work great in places where corrosion is a problem. The reason behind this comes down to how the polymer molecules are arranged, letting the material handle contact with all sorts of stuff like acids, bases, oils, and solvents that show up regularly in factories. Take chemical plants for instance, where workers have used these sheets for years because they don't break down when exposed to aggressive substances. Compared to alternatives like acrylic or polycarbonate, PVC just holds up better over time. Real world testing shows companies that switch to PVC for things like storage tanks and reaction vessels see their equipment last longer between replacements. Maintenance crews also report fewer headaches since there's less need for repairs or part swaps. While nothing beats pure glass for some specialized applications, most industrial settings find PVC offers an excellent balance between protection and practicality without breaking the bank.

Thermal Insulation Properties for Energy Savings

PVC clear sheets have good thermal insulation properties, so they work well as an energy efficient option. They stop heat from moving through easily, something that matters a lot when trying to save money on energy in commercial buildings. Companies that switched to PVC sheets saw their energy bills go down quite a bit. Some even reported cutting heating and cooling costs by around 30%. Over time, this kind of energy saving adds up to lower operating costs and helps the environment too. When businesses invest in these insulating sheets, they tend to see real savings on their monthly bills plus contribute to greener practices without sacrificing functionality.

Moisture and Corrosion Resistance Comparison

PVC clear sheets really stand out when we talk about resisting moisture and corrosion compared to traditional options like wood or metal. Wood tends to soak up water while metal gets rusty over time, but PVC just doesn't care about getting wet or oxidizing. The difference in longevity is pretty impressive too. Take a look at what happens in damp conditions – PVC lasts way longer than regular wood would, sometimes lasting twice as long or more. That's why so many industries where keeping things dry matters most end up choosing PVC sheets. Marine businesses rely on them for boat covers, farmers use them for greenhouse panels, and construction crews install them wherever there might be water issues. These sheets protect equipment and buildings from water damage year after year, saving money on replacements and maintenance costs.

Light Transmission Capabilities vs. Polycarbonate

When it comes to letting light through, PVC clear sheets have some serious advantages that put them right up there with polycarbonate materials, especially when clear visibility matters most. These sheets deliver pretty good optical clarity plus they block out a lot of those damaging UV rays, which makes them great for places where consistent lighting is needed day after day. Some research has actually shown that PVC can hold its own against polycarbonate when measuring how much light gets through, often matching the clarity while still protecting against sun damage. Greenhouses are one prime example where these properties really shine (pun intended). Farmers need just the right amount of sunlight reaching their plants without burning them, and PVC helps strike that balance between protection and proper illumination for healthy crop development.

Installation and Maintenance Guidelines

Proper Mounting Techniques for Strip Curtain Doors

Mounting strip curtain doors correctly is crucial for their optimal functionality and longevity. Here are step-by-step instructions to assist in the installation process:

1. Preparation:

- Measure the space accurately to ensure the curtain fits perfectly.

- Gather necessary tools, including drills, screws, brackets, and safety gear.

2. Installation:

- Position the mounting brackets at the top of the door frame and secure them tightly.

- Ensure each PVC strip is aligned uniformly for seamless coverage.

- Secure the strips in place using screws on the brackets.

3. Adjustment:

- Check for proper strip alignment to avoid excessive wear and tear.

- Ensure the strips have enough overlap to maintain efficiency.

It is essential to align and securely mount strip curtain doors to prevent damage and extend their lifespan. A checklist can be invaluable to installers during this process.

Cleaning Methods to Maintain Optical Clarity

Proper cleaning techniques are vital to preserving the transparency and performance of PVC clear sheets. Here are recommended solutions and steps:

- Cleaning Solutions: Use non-abrasive, pH-neutral cleaning agents. Avoid solvents that could damage the PVC material.

- Techniques: Apply the cleaning solution gently with a microfiber cloth. Rinse thoroughly with clean water and dry with a soft cloth to prevent water spots.

- Common Mistakes to Avoid: Refrain from using abrasive pads or brushes that can scratch surfaces. Avoid high-pressure washers which may deteriorate the material.

Expert opinions from industry leaders emphasize regular maintenance to prolong the optical clarity of PVC sheets.

Repairing Scratches and Surface Damage

Minor scratches on PVC clear sheets can be repaired using simple methods and materials, while severe damage may require professional intervention.

- Repair Techniques: Minor scratches can be buffed with auto polishing compounds. Use a soft cloth to apply the compound and gently smooth the surface.

- Professional Refinishing Services: Consider professional services for deep scratches or extensive surface damage. Experts can restore both aesthetic and functional qualities effectively.

Timely repairs are essential to maintaining clarity and durability. Addressing damage promptly prevents further deterioration.

When to Replace Industrial Plastic Door Curtains

Recognizing when to replace PVC strip curtains is imperative to ensure safety and efficacy.

- Signs for Replacement: Observe for discoloration, tearing, or brittleness in the material. Frequent malfunctions during operation, like difficulty opening or closing.

- Factors Affecting Longevity: UV exposure, heavy usage, and fluctuating environmental conditions impact lifespan.

- Recommendations: Conduct regular inspections at least bi-annually. Replace curtains based on observed damage or degradation levels.

Regular inspections can prolong the efficiency and safety of industrial plastic door curtains, ensuring they serve their intended purpose without compromise.